- Lithium battery ultra-low drew point mac...

- Honeycomb-typed rotary dehumidifiers...

- Patent Glove Chamber Of Low-Dew Point De...

- NMP recovery machine...

- Small rotor dehumidifier...

- Wheel dehumidifiers...

- Assembly-type dehumidifier...

- The assembly type purification dehumidif...

- Low temperature low humidity desiccant u...

- Dehumidification units for low dew point...

|

| |

One Corner of lithium battery drying chamber (Hitachi Maxell, first phase) | ZHS-□-SDP ultra-low drew point dehumidifying and drying system(temperature 20~25℃, relative humidity, 0.1~5%RH,drew point-75℃dp, wind rate processing capacity: 300~30000m3/h) | |

|

| |

| Drew point display value of lithium battery drying chamber (Hitachi Maxell) | Lithium battery drying chamber in use (Hitachi Maxell, first phase) | |

|  | |

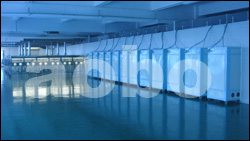

| Machine room (Hitachi Maxell, second phase) | Machine room (Hitachi Maxell, Japan. At the left is the second phase machine set and right is the first phase machine set) | |

|  | |

| Drew point | Drying chamber (Hitachi Maxell, second phase) | |

|  | |

| Drying chamber and glove-box (McNair High-tech Co., Ltd) | Drying chamber and glove-box (McNair High-tech Co., Ltd) | |

|  | |

| Drew point inside of drying chamber | Machine set | |

|  | |

| Drying chamber (McNair High-tech Co., Ltd) | Drying chamber (BAK Battery) |

| Item | Operator | Wind rate processing capacity | RecoveryMethod* | RecoveryMethod(Electric) | Cooling load | Dehumidifyingspace | Power of refrigerator |

| person | m3/h | KW | KW | KW | m3 | KW | |

| ZHS-450 | 1~3 | 500~800 | 9~13 | 19~32 | 38~92 | 25~40 | 12.5~30.4 |

| ZHS-550 | 2~4 | 800~1000 | 11~18 | 27~43 | 56~187 | 40~60 | 18.5~51 |

| ZHS-770 | 3~5 | 1500~2800 | 7.5 | 66~98 | 92~220 | 60~90 | 30.4~66 |

| ZHS-950 | 4~8 | 2800~4000 | 11~15 | 82~130 | 110~260 | 90~150 | 36.4~78 |

| ZHS-1200 | 10~20 | 4000~6000 | 19~27 | - | 180~430 | 100~230 | 54~129 |

| ZHS-1500 | 18~40 | 7000~10000 | 31~48 | - | 228~640 | 230~370 | 68.5~192 |

| ZHS-1900 | 50~80 | 9000~15000 | 39~55 | - | 390~1425 | 370~500 | 117~426 |

| ZHS-2400 | 100~150 | 12000~20000 | 50~72 | - | 700~1600 | 500~670 | 210~480 |

| ZHS-3000 | 200~250 | 18000~30000 | 90~110 | - | 870~2350 | 670~830 | 261~705 |

Note:

1.wind speed of rotary wheel surface: m/S design

2.To ensure the normal breath of operators and plus pressure of drying chamber, supplying new air should be calculated by 20~30m/h per person, plus pressure should be calculated by the times of drying chamber area, and take the max. value of them. Outside air condition is 36℃,relative humidity 70%, absolute moisture content 26.8g/kg dry air.

3.Moisture load of operator calculated by g/h. Before entering into drying chamber the operators should come to buffer chamber.

4.The recovery method* can select and use steam, fuel oil, natural gas, liquefied gas, and city gas.

5.Power of dehumidify fan and air blow-in fan is not contained in the power of ZHS-770~ZHS-3000 rotary dehumidifier. Power supply: three phase 380V50HZ.

6.The outline dimension of machine set can be verified by the actual needs of users. 7.Because of the continual development of technology, the actual technical parameters should be in accordance with the altered parameters.